Global Design-to-Manufacturing Support for Hardware Teams

We provide private Shenzhen design & engineering labs, accelerated EVT/DVT testing, cost-effective pilot builds, and flexible global mass production paths—launch new products faster.

Our customers are product design firms, high growth brands, corporate engineering teams, and hardware entrepreneurs. We leverage Shenzhen-based design engineering, validation, and NPI to de-risk programs, then help you scale wherever it makes sense.

Manufacturing Technology

Full-Service Product Design & Validation

Prove out your architecture in Shenzhen with our design engineering team, validation labs, and supply partners—then scale production in the geography that best fits your cost, compliance, and logistics targets.

Accelerated EVT/DVT Testing

Local labs and fixtures shorten compliance and reliability testing cycles so issues surface before tooling locks in.

Pilot & NPI Builds

Small-batch SMT, mechanical, and assembly runs validate your BOM, firmware, and QA plans ahead of MFG release or transfer.

Global Production Transfer

Once the product is stable, we analyze low-cost country options and manage the transfer—or keep mass production in-region if that best meets the brief.

Integrated Collaboration

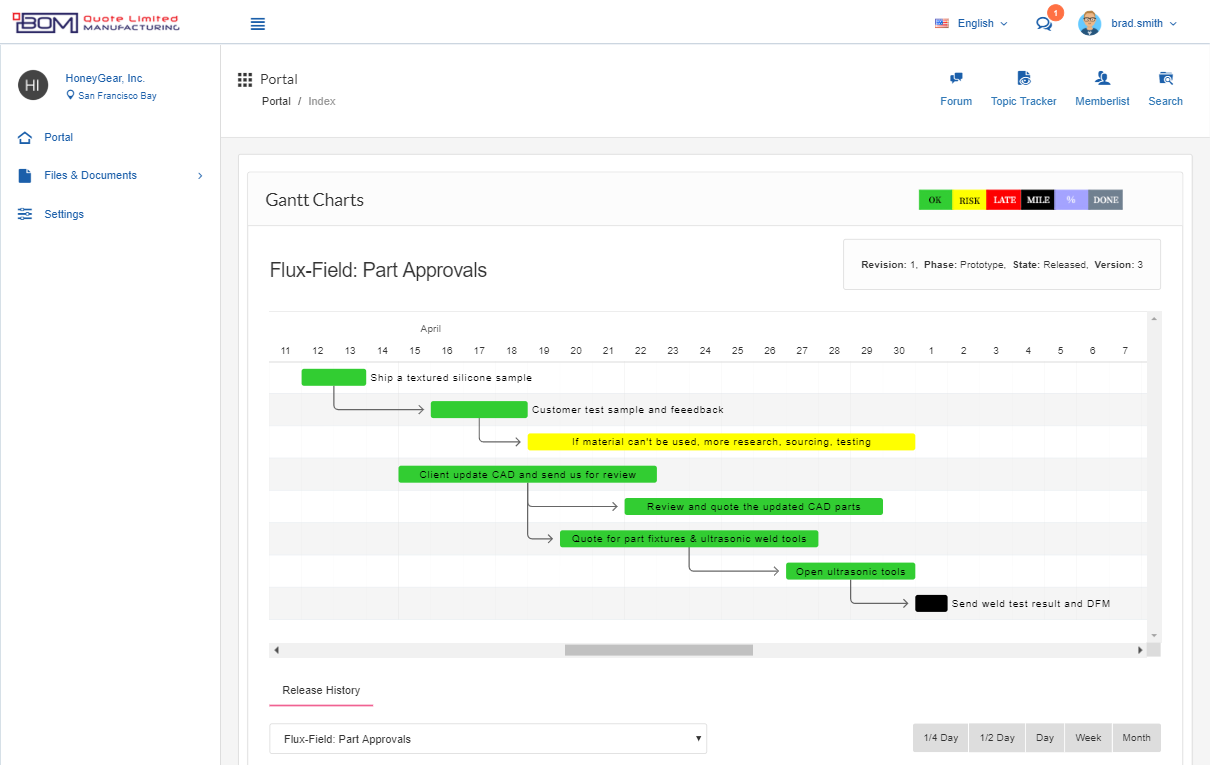

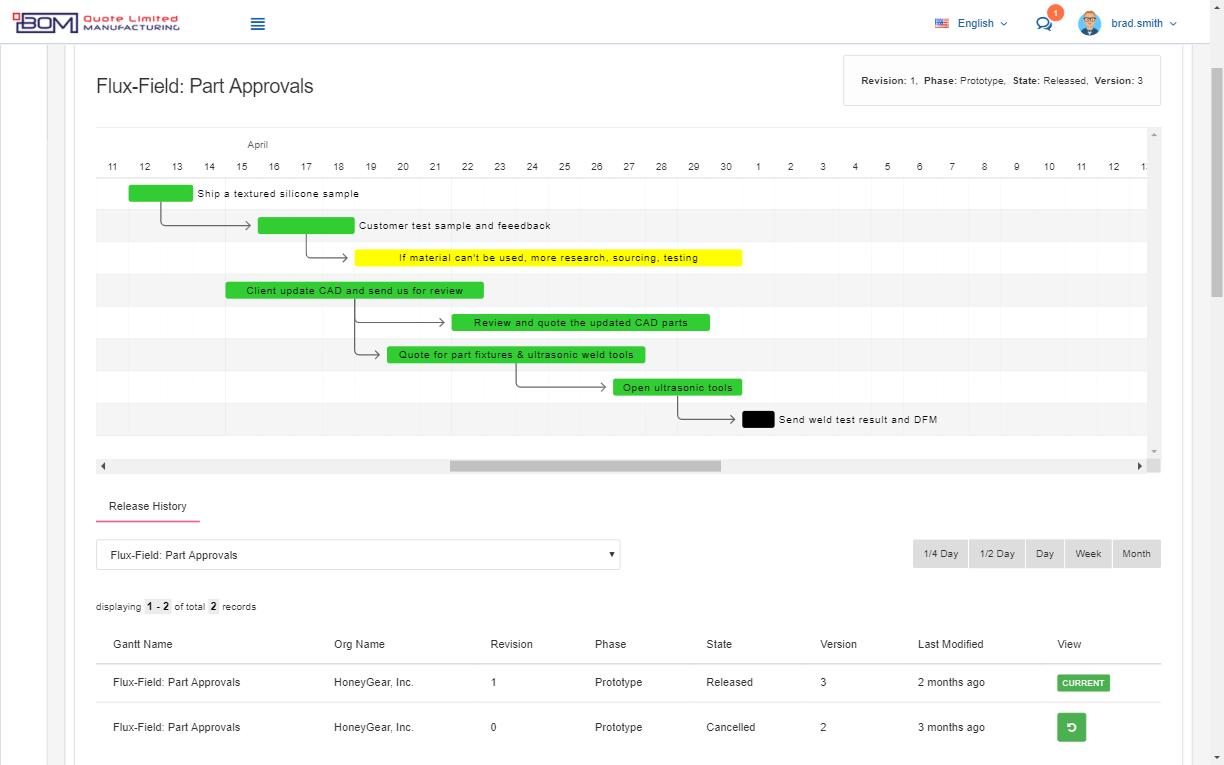

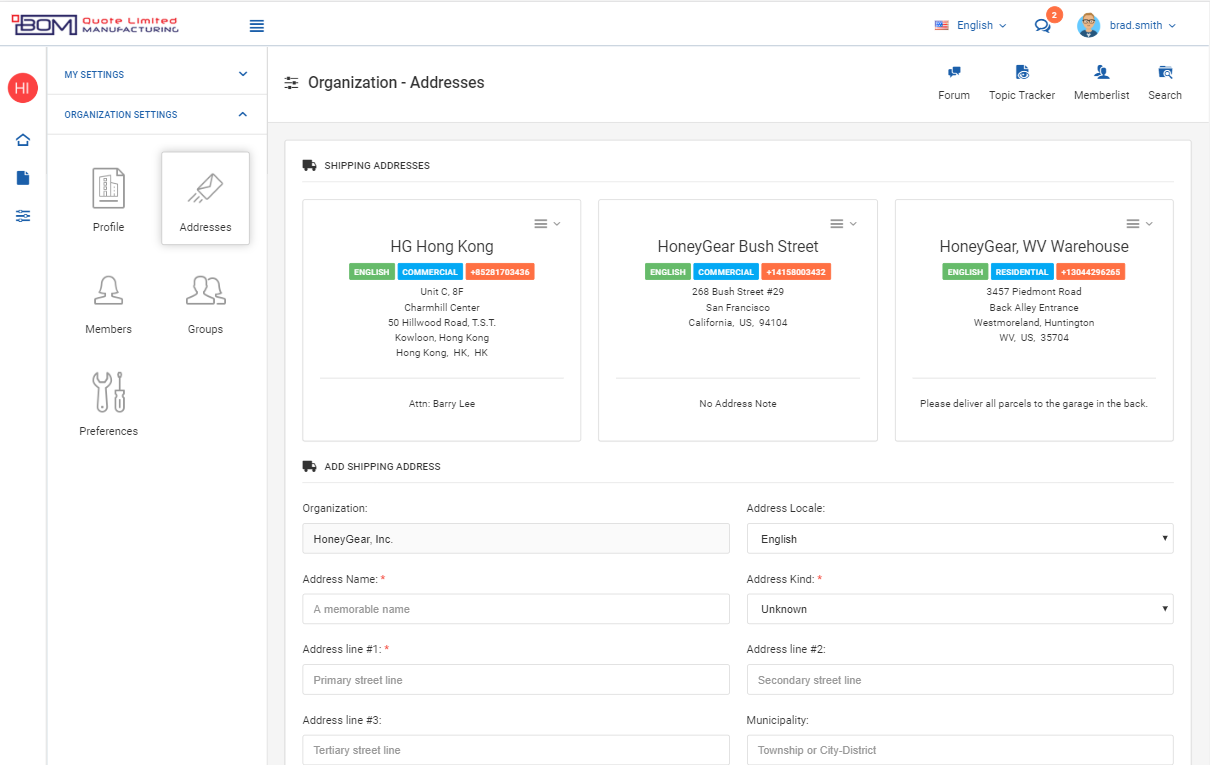

Shared dashboards for BOMs, ECOs, QA, logistics, and finance keep global stakeholders aligned from concept through launch.

Poor communication and management of joint project timelines result in project failures. Our bomquote.com platform provides communication and project management tools to ensure global project teams are successful.

English

English  简体中文

简体中文